Inventory levels refer to the quantity of goods and materials a business holds across its logistics network, including warehouses, retail outlets, and distribution centers. Maintaining optimal inventory levels is critical for operational efficiency, cost management, and customer satisfaction. This article discusses the concept of inventory levels, their types, importance, and strategies for effective management.

Understanding Inventory Levels

Inventory levels assess the stock available at any given time, encompassing raw materials, work-in-progress, and finished goods. Striking the right balance between too much and too little inventory is vital for smooth business operations. Excess inventory ties up capital and incurs storage costs, while insufficient inventory leads to missed sales and customer dissatisfaction.

Key Goals of Managing Inventory Levels:

- Meet customer demand without delays.

- Minimize holding costs.

- Avoid stockouts and overstock scenarios.

- Enhance operational efficiency and cash flow.

Importance of Inventory Levels

Effective inventory management directly impacts profitability and customer satisfaction. Below are some of the primary benefits:

- Cost Efficiency: Excess inventory increases warehousing, insurance, and handling costs. Optimal levels reduce expenses by minimizing overstock and obsolescence.

- Customer Satisfaction: Maintaining adequate stock ensures timely order fulfillment, enhancing customer loyalty.

- Operational Efficiency: Balanced inventory levels streamline supply chain processes and reduce disruptions.

- Financial Health: Proper inventory management frees up capital tied in excess stock, improving cash flow.

Types of Inventory Levels

Understanding and calculating inventory levels help businesses maintain a strategic balance. Here are the key types:

Minimum Inventory Level

The minimum inventory level represents the safety stock required to prevent stockouts. It ensures that a business has enough raw materials or products to meet unexpected demand or supply chain delays.

Formula:

Minimum Inventory Level = Average Usage × Average Lead Time

Example: If a company uses 50 units per day and lead time is 5 days, the minimum inventory level is 250 units.

Maximum Inventory Level

The maximum inventory level refers to the highest quantity of stock a company can store without incurring unnecessary costs or space issues.

Formula:

Maximum Inventory Level = Reorder Level + Reorder Quantity – (Minimum Usage × Minimum Purchase Time)

Key Considerations: Storage capacity, carrying costs, and risks of pilferage or obsolescence.

Optimal Inventory Level

Optimal inventory levels strike a balance between meeting customer demand and minimizing storage costs. They allow businesses to operate efficiently without overstocking or stockouts.

Reorder Point (ROP)

The reorder point is the stock level at which a new order should be placed to replenish inventory before it runs out.

Formula:

Reorder Point = Maximum Consumption Rate × Maximum Reordering Period

Safety Stock

Safety stock acts as a buffer against demand fluctuations and lead time variability, ensuring uninterrupted operations.

Factors Influencing Inventory Levels

Several factors determine optimal inventory levels for a business:

- Demand Forecasting: Accurate forecasting helps predict future sales, ensuring the right stock levels.

- Lead Time: Longer lead times require higher safety stock to avoid disruptions.

- Seasonality: Businesses must adjust inventory for seasonal demand variations.

- Carrying Costs: Includes storage, insurance, and capital tied up in inventory.

- Economic Order Quantity (EOQ): EOQ calculates the ideal order size to minimize total costs.

- Product Shelf Life: Perishable or time-sensitive goods require precise inventory control to avoid wastage.

- Market Trends: Shifts in consumer preferences influence stock requirements.

Methods to Calculate Inventory Levels

Effective inventory management relies on accurate calculations. Here are three key methods:

Min-Max Inventory Levels

This method sets minimum and maximum thresholds for stock levels. When inventory falls to the minimum level, a new order is placed to replenish stock to the maximum level.

Formulas:

- Minimum Inventory Level = (Average Daily Usage × Lead Time) + Safety Stock

- Maximum Inventory Level = Minimum Inventory Level + Reorder Quantity

Average Inventory Level

This method calculates the average stock held during a specific period.

Formula:

Average Inventory Level = (Beginning Inventory + Ending Inventory) / 2

MRP Inventory System

Material Requirements Planning (MRP) uses demand forecasts and production schedules to determine the precise amount and timing of inventory replenishments.

Strategies to Optimize Inventory Levels

Optimizing inventory levels is essential for minimizing costs and maximizing efficiency. Below are some proven strategies:

Just-in-Time (JIT) Inventory Management

JIT minimizes excess inventory by aligning stock replenishment with actual demand. It reduces carrying costs and risks of obsolete inventory but requires accurate forecasting and reliable suppliers.

ABC Analysis

This technique categorizes inventory into three groups based on importance:

- A: High-value items with low quantity.

- B: Moderate-value items.

- C: Low-value items with high quantity.

Vendor-Managed Inventory (VMI)

VMI transfers responsibility for inventory management to suppliers, ensuring timely replenishments without overstocking.

Inventory Audits and Cycle Counting

Regular audits and cycle counting help identify discrepancies, slow-moving items, and obsolescence.

Digitization and Technology Adoption

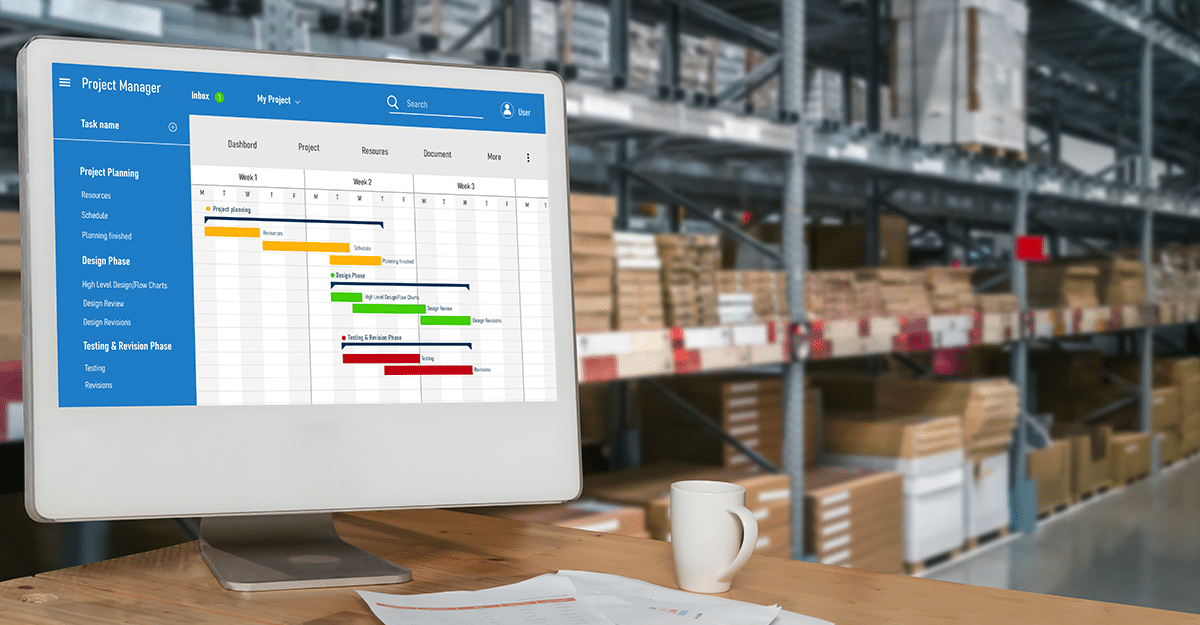

Using inventory management software streamlines tracking, forecasting, and decision-making through real-time data insights.

Role of Digitization in Inventory Management

Digital tools have revolutionized inventory management by improving accuracy, efficiency, and responsiveness.

Real-Time Tracking

Technologies like RFID tags, barcodes, and IoT devices enable businesses to monitor inventory across multiple locations.

Forecasting Demand

AI and machine learning analyze historical data, market trends, and customer behavior to predict demand accurately.

Automation

Warehouse Management Systems (WMS) automate tasks like procurement, stock transfers, and inventory tracking, reducing human error.

Cloud-Based Solutions

Cloud-based inventory management allows remote access and coordination across multiple facilities, enhancing scalability.

Analytics and Reporting

Dashboards and visualization tools provide actionable insights to optimize stock levels and identify inefficiencies.

Challenges in Managing Inventory Levels

- Multi-Location Management: Coordinating inventory across multiple sites increases complexity.

- Demand Variability: Fluctuations in customer demand can lead to overstock or stockouts.

- Supply Chain Disruptions: Delays in procurement or transportation affect inventory levels.

- Storage Constraints: Limited space requires precise stock calculations.

- Obsolescence: Perishable goods and outdated products impact profitability.

Benefits of Maintaining Optimal Inventory Levels

Improved Cash Flow: Reduces capital tied up in excess inventory.

- Customer Satisfaction: Ensures timely delivery of products.

- Cost Savings: Minimizes storage, insurance, and obsolescence costs.

- Operational Efficiency: Streamlines supply chain processes and reduces waste.

- Competitive Advantage: Businesses with effective inventory management are better positioned to adapt to market changes.

Conclusion

Inventory levels are a cornerstone of effective business management. By understanding and strategically managing inventory, businesses can minimize costs, improve efficiency, and ensure customer satisfaction. Employing techniques like JIT, ABC analysis, and leveraging digital tools such as WMS and cloud-based solutions empowers businesses to maintain optimal stock levels in today’s dynamic market. Striking the right balance is key to long-term success and profitability.

FAQs

Why are inventory levels important?

Managing inventory levels helps businesses avoid stockouts, reduce storage costs, and ensure timely order fulfillment. It also improves cash flow and operational efficiency while meeting customer expectations.

What is the difference between minimum and maximum inventory levels?

Minimum inventory levels are the safety stock required to avoid stockouts, while maximum inventory levels represent the upper limit of stock a business can store without incurring excess costs.

What happens if inventory levels are too high?

Excess inventory ties up capital, increases storage costs, and risks obsolescence or damage. It can also reduce overall profitability for a business.

How can businesses calculate ideal inventory levels?

Businesses use methods like Min-Max calculations, Economic Order Quantity (EOQ), and Reorder Points (ROP) to determine the right stock levels based on demand, lead time, and storage capacity.

What is the role of safety stock in inventory levels?

Safety stock acts as a buffer to handle demand fluctuations or supplier delays, ensuring uninterrupted operations and preventing stockouts.

How does technology improve inventory level management?

Inventory management software and tools like WMS provide real-time tracking, automate replenishment, and use data analytics to optimize stock levels and improve decision-making.

What is the optimal inventory level?

Optimal inventory level is the right amount of stock needed to meet customer demand without overstocking or risking stockouts. It balances supply, demand, and costs effectively.

How can businesses reduce excess inventory?

Businesses can reduce excess inventory by implementing Just-in-Time (JIT) strategies, conducting regular audits, improving demand forecasting, and using inventory management software to monitor stock levels in real-time.

I’m Tammy Waller, a supply chain and logistics specialist with over 10 years of expertise. I’ve been an author and SFL employee for over 10 years.

As an author, I’ve been able to teach others. I love guiding users through supply chain and logistics operations.

I have substantial experience managing logistics operations, supply chain management, transportation, inventory management, and warehousing in shipping-moving and logistic services. I’ve worked on many worldwide logistics and supply chain projects, honing my abilities in negotiating rates, scheduling shipments, and managing vendors.